Humidity and moisture measurement play a critical role in a wide range of industrial applications. From the agricultural sector to food processing, building construction to environmental testing, the ability to accurately measure and control humidity is vital to maintaining product quality, ensuring safety, and improving operational efficiency. Moisture levels, if not precisely monitored, can affect materials, products, and processes, potentially causing damage, inefficiencies, or failures. This makes the need for reliable and accurate humidity and moisture measurement devices, such as IEC Water Vapor Devices, essential in various industries.

IEC Water Vapor Devices are specifically designed to provide highly accurate and consistent measurements of water vapor in the air. These devices help industries monitor and control moisture content, ensuring product integrity, safety, and regulatory compliance. This article delves into the importance of humidity and moisture measurement, the working principles of IEC water vapor devices, their key applications, and methods for ensuring accurate measurements.

The Importance of Humidity and Moisture Measurement in Industrial Applications

In many industries, maintaining the right levels of humidity is crucial for the success of the production process. Excess moisture or insufficient moisture can lead to several problems, such as:

Material degradation: In industries like construction, improper humidity control can cause materials such as wood, concrete, and metals to degrade, warp, or corrode over time.

Product quality issues: In the food and beverage industry, incorrect moisture levels can cause spoilage, mold growth, or texture degradation, leading to waste and quality issues.

Safety concerns: In electrical and manufacturing applications, excess moisture can increase the risk of electrical short circuits, equipment failure, or fire hazards.

Regulatory compliance: For industries like pharmaceuticals and electronics, accurate moisture control is crucial to meet stringent regulatory standards. The right moisture levels are necessary for proper storage, packaging, and testing of products.

Given these challenges, the importance of precise and reliable moisture and humidity measurement cannot be overstated. This is where IEC Water Vapor Devices become indispensable.

IEC Water Vapor Devices in Ensuring Accurate Humidity Measurement

IEC Water Vapor Devices are engineered to offer precise measurements of water vapor in the air. These devices play an essential role in maintaining control over humidity levels across various applications, ensuring that measurements are both reliable and accurate. Below, we explore the working principles of these devices and how they contribute to accurate moisture measurement.

Working Principle of IEC Water Vapor Devices

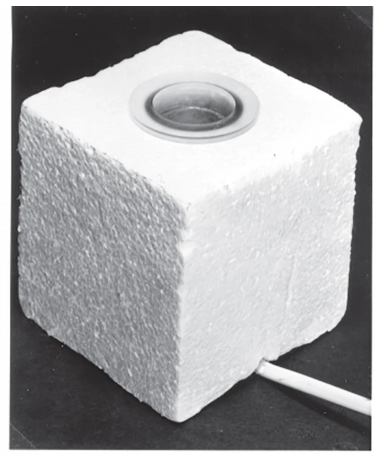

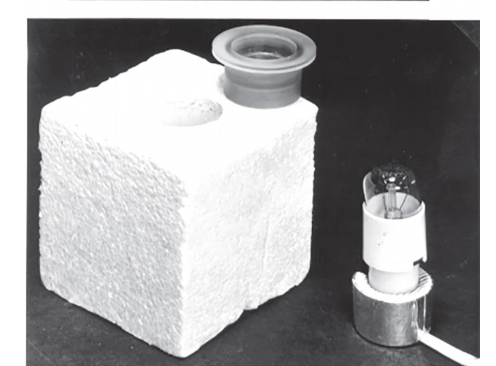

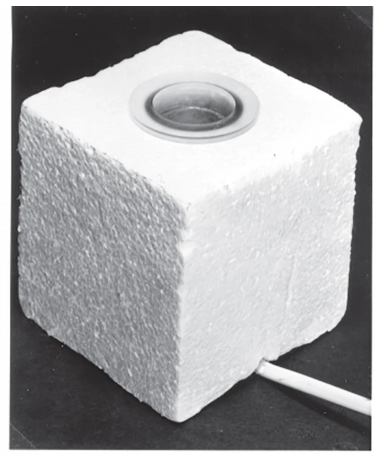

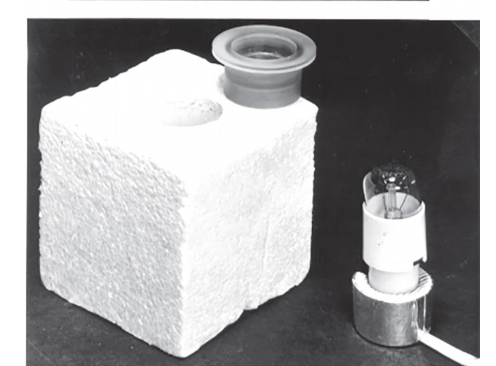

IEC Water Vapor Devices operate by measuring the amount of water vapor in the air and translating this information into usable data. The main principle behind these devices is to simulate and measure water vapor through advanced sensor technology.

Simulating and Measuring Water Vapor:

Water vapor sensors are used in these devices to detect moisture levels in the air. They work by measuring the electrical resistance or capacitance changes that occur when water vapor comes into contact with the sensor.

The device collects air samples and passes them through a sensor or probe that reacts to the moisture in the air. The sensor's response correlates to the amount of water vapor present, which is then displayed as a moisture level or humidity reading.

Advanced Technology for Precision Measurement:

The accuracy of IEC Water Vapor Devices is largely due to the advanced sensor technology used in these devices. Capacitive and resistive sensors are among the most common technologies employed. Capacitive sensors measure changes in the dielectric constant of materials due to the presence of water vapor, while resistive sensors detect variations in electrical resistance as moisture content increases.

Humidity sensors in these devices offer high sensitivity and can measure minute changes in water vapor concentrations, providing highly accurate readings across a wide range of conditions. These sensors often employ highly specific materials that react predictably to water vapor, allowing for consistency in measurements.

Calibration for Accuracy:

The performance of water vapor devices depends heavily on proper calibration. IEC Water Vapor Devices are designed to be calibrated to international standards, ensuring they provide consistent and accurate measurements over time.

Regular calibration ensures that devices remain accurate, even when environmental conditions change. This is particularly important in industries where precise humidity control is necessary for product quality and safety.

Applications of IEC Water Vapor Devices

IEC Water Vapor Devices are essential tools in various industries. Below are some of the key sectors where these devices are used to monitor and control moisture levels:

Environmental Testing:

In environmental testing, IEC Water Vapor Devices simulate and monitor the moisture content of air in controlled environments. This is crucial for testing the effects of humidity on materials and products, such as electronic devices, construction materials, and more. Accurate moisture measurement is key for environmental simulations, as it helps manufacturers predict how products will perform under real-world conditions.

Building Construction:

Proper humidity control is essential for ensuring the quality and longevity of building materials such as wood, concrete, and drywall. Excess moisture can weaken structures and cause mold or corrosion, while too little moisture can cause materials to crack or dry out. Using IEC Water Vapor Devices ensures that humidity levels are accurately controlled, preventing these issues and improving construction project outcomes.

Food Processing and Agriculture:

In the food industry, moisture levels in products like grains, meats, and dairy must be precisely monitored to avoid spoilage, mold growth, and loss of texture. IEC Water Vapor Devices help food manufacturers ensure that humidity levels are optimal for storage, packaging, and transportation.

In agriculture, these devices are used to monitor the moisture content of soil, which is vital for crop health and irrigation management. Accurate measurements ensure that crops receive the right amount of water, improving yields and preventing water waste.

Pharmaceuticals and Electronics:

Humidity control is critical in the pharmaceutical industry to ensure the stability and efficacy of products. IEC Water Vapor Devices help monitor the storage environment of sensitive drugs and vaccines, ensuring that they remain within acceptable moisture ranges.

In electronics, excess moisture can damage sensitive components and cause failures. IEC Water Vapor Devices are used to ensure that electronic products are tested and stored in environments with controlled humidity levels, preventing damage and ensuring long-term reliability.

Ensuring Measurement Accuracy: Key Methods

To ensure the accuracy of measurements, several factors come into play, including sensor technology, calibration, and maintenance. The following methods help increase the reliability and consistency of moisture measurements:

High Precision Sensors:

High-quality sensors are critical in ensuring that measurements are accurate and consistent. IEC Water Vapor Devices use sensors that are specifically designed for precise moisture detection, offering reliability even under challenging conditions.

These sensors are sensitive to small changes in humidity, which is especially important in industries requiring high levels of precision, such as pharmaceuticals and electronics.

Regular Calibration:

Calibration is essential for maintaining the accuracy of moisture measurements. Regular calibration against known reference standards ensures that devices continue to deliver reliable data over time.

Many IEC Water Vapor Devices come with built-in calibration features or offer the option for calibration in the field, allowing businesses to maintain the highest standards of measurement accuracy.

Routine Maintenance:

Routine maintenance of IEC Water Vapor Devices ensures that sensors remain free from dirt, dust, or other contaminants that could affect their accuracy. Regular cleaning and inspection also help extend the lifespan of the equipment.

Conclusion

IEC Water Vapor Devices are indispensable tools for ensuring accurate humidity and moisture measurement across a wide range of industries. With advanced sensor technology, calibration features, and high-precision measurement capabilities, these devices play a vital role in controlling moisture content, ensuring product quality, and meeting regulatory standards. Industries like construction, food processing, agriculture, electronics, and pharmaceuticals all benefit from the accurate and reliable moisture measurements provided by these devices.

Investing in IEC Water Vapor Devices allows businesses to improve product quality, reduce risks associated with moisture-related issues, and optimize operational efficiency. For industries where humidity control is critical, these devices offer the reliability and accuracy needed to ensure long-term success and compliance with industry standards.

To learn more about how IEC Water Vapor Devices can enhance your moisture measurement processes, consider reaching out to Guangzhou Zhilitong Electromechanical Co., Ltd. Their cutting-edge solutions are designed to meet the needs of diverse industries and help businesses achieve optimal results.