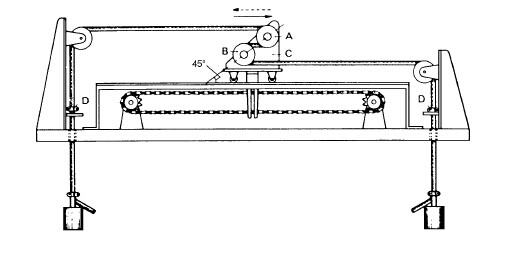

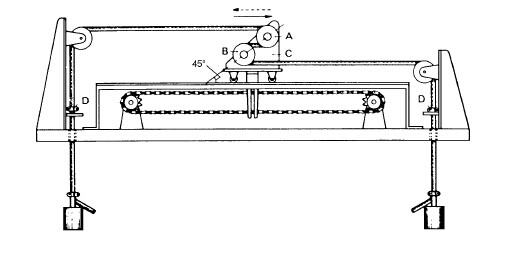

Flexible Cable Flexing Test Apparatus

IEC60245.2 Rubber Cables Flexing Test Apparatus

Product details: Model ZLT-QL1.

For checking the mechanical durability of flexible cords and cables by bending them back and forth, This test does not apply to flexible cables with cores of nominal cross-sectional area greater than 4㎜2,nor to cables having more than 18 cores laid up in more than two concentric layers, according to IEC60245-2/1998-04 figure 1, IEC60227-2/1997-11 figure 1, IEC60065 /1998-07 Table 11,EN50396 clause 6.2 and figure 4.

Standard Outfit:

1 carrier, with recirculating-ball bearing bushes running below the table-board on two cylindrical guideways, with mounted travelling boom,

1 geared motor with chain and connecting rod to drive the carrier with a speed 0,33 m/s±5%,

1 set per sample of bolts and nuts for fastening the pulleys,

1 set per sample of restraining clamps and stops to limit the travel of the sample,

1 set per sample of instrument terminals or – after agreement-plugs and socket-outlets for connection of sample,

1 set per sample of clamps to fasten the samples beneath the instrument terminals,

1 set pulleys of diameter 60mm-80mm-120mm-160mm-200mm,

1 set weights from 0,5 kg to 8 kg,

1 electrical switching and control unit with main switch, lockable switch,

1 electrical control system of load current 0~25A, load voltage 0~400V, testing stops when current interruption, short circuit between the wires, short circuit between the sample and the pulley.

Power supply: 380V 50Hz, other voltage on request.