Product Overview

The ZLT-HVL High Voltage Arc Ignition Tester (by ZLTJC) is a professional solution for evaluating the arc resistance of insulating materials. Fully compliant with UL746A clause 22.2, IEC61621, and ASTMD495, it tests whether materials can resist the formation of conducting paths caused by high-voltage, low-current arcs—critical for preventing short circuits in electrical devices. The ZLT-HVL delivers adjustable high voltage up to 12.5 KV and selectable arc currents (10 mA, 20 mA, 30 mA, 40 mA), making it ideal for testing plastics, resins, and electrical insulation components. Manufactured in China (shipped from Guangzhou Port), it has a lead time of 30 days, MOQ of 1 unit, and accepts T/T payments—providing a reliable tool for material science labs and electronics manufacturers.

Technical Parameters

Parameter Category | Specification Details |

Model | ZLT-HVL |

Standard Compliance | UL746A clause 22.2, IEC61621, ASTMD495 |

Maximum High Voltage | Adjustable up to 12.5 KV |

Arc Current Range | 10 mA, 20 mA, 30 mA, 40 mA (via R10/R20/R30/R40 resistors) |

Current Measurement | AC milliammeter (range: 10 ~ 40 mA; error: ≤±5%) |

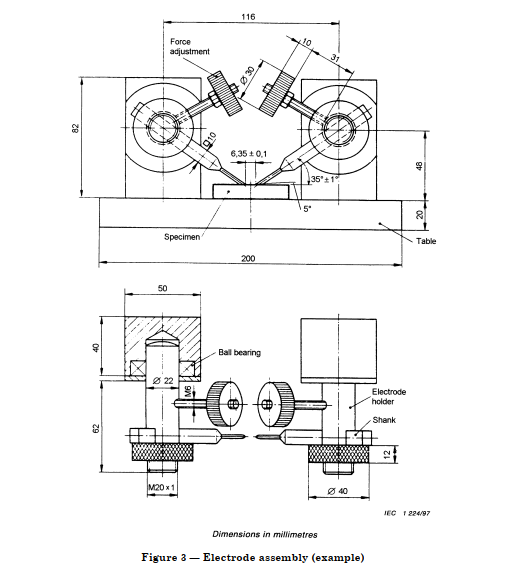

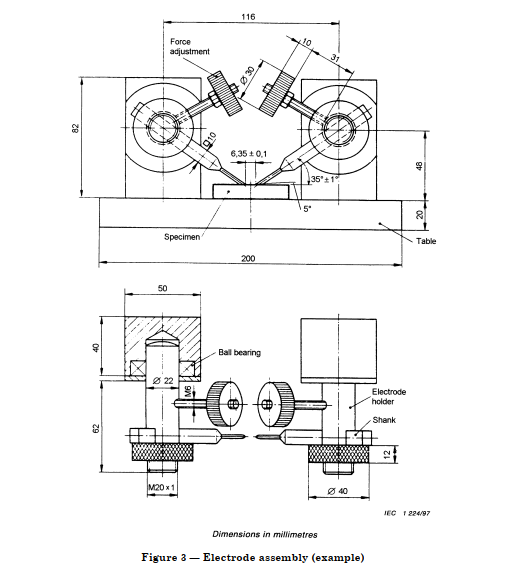

Electrode Specifications | - Material: Tungsten rod (crack/pit-free)- Diameter: 2.4 mm ± 0.05 mm- Tip Angle: 30° ± 1°- Minimum Free Length: 20 mm |

Electrode Force | 0.5 N ± 0.05 N (independent contact with specimens) |

Electrode Tip Spacing | 6.35 mm ± 0.08 mm (measured via dedicated gauge) |

Test Chamber | Enclosed (no venting); dimensions: ≥300 mm × 150 mm × 100 mm |

Power Supply | 220V 50Hz (custom voltages available) |

Payment Term | T/T (Telegraphic Transfer) |

Lead Time | 30 days |

MOQ | 1 unit |

Product Features

Multi-Standard Compatibility

Compliance with UL746A, IEC61621, and ASTMD495 allows the ZLT-HVL to test materials for global markets—from North America (UL standards) to Europe (IEC standards). This eliminates the need for multiple testers, cutting lab costs.

Precise Arc Generation and Measurement

Adjustable high voltage (up to 12.5 KV) and selectable currents (10~40 mA) simulate diverse electrical environments, from low-power electronics to high-voltage industrial equipment.

The AC milliammeter (error ≤±5%) ensures accurate current measurement, critical for interpreting arc resistance results and ensuring compliance.

High-Quality Electrode Design

Tungsten electrodes (2.4 mm ± 0.05 mm diameter) are polished to a 30° ± 1° tip angle, ensuring consistent arc initiation. The 0.5 N ± 0.05 N contact force guarantees uniform pressure on specimens, preventing variable results.

Safe and Stable Test Environment

The sealed test chamber (≥300 mm × 150 mm × 100 mm) contains high-voltage arcs, protecting operators from hazards. It also maintains a stable environment (temperature, humidity) for repeatable results.

Application

The ZLT-HVL High Voltage Arc Ignition Tester is vital for industries relying on insulating materials:

Electronics: Testing PCB insulation, wire coatings, and capacitor housings to resist arc damage in power supplies and inverters.

Electrical Equipment: Evaluating resins for transformers, motors, and switchgear—arc resistance prevents short circuits and equipment failure.

Automotive: Assessing EV components (battery enclosures, wiring harnesses) to withstand high-voltage environments and ensure passenger safety.

Material Labs: Researching new insulating materials (e.g., high-temperature polymers) by measuring arc resistance per global standards.

FAQ

Q: What arc current options does the ZLT-HVL offer?

A: It supports four current levels—10 mA, 20 mA, 30 mA, and 40 mA—controlled via dedicated resistors (R10 to R40) for flexible testing.

Q: Why is the electrode tip angle important?

A: The 30° ± 1° tip angle ensures consistent arc initiation at the specimen surface. A uniform angle prevents variations in arc intensity that could skew test results.

Q: Is the ZLT-HVL safe to operate?

A: Yes, the sealed test chamber contains high-voltage arcs, and all components comply with safety standards. Proper grounding (per manufacturer guidelines) is required for safe operation.

Q: Can the ZLT-HVL be customized for non-standard voltages?

A: The standard power supply is 220V 50Hz, but custom voltages (e.g., 110V 60Hz) are available. Contact the manufacturer to discuss customization and lead time adjustments.