Product Overview

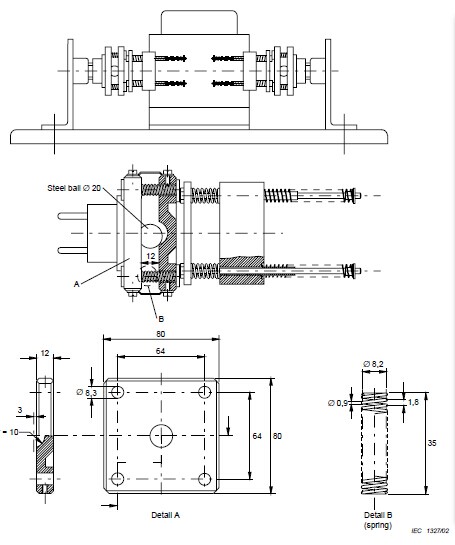

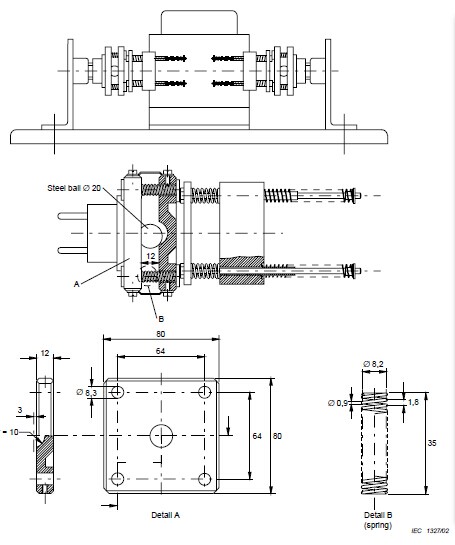

We are professional manufacturers of Plug And Socket Normal Operation Test Machine, dedicated to evaluating the performance and durability of household and similar electrical accessories. This test machine is strictly designed in accordance with IEC 60884-1 figure 16 and clause 20, focusing on two core indicators: the breaking capacity of plugs, socket-outlets, cable couplers, and appliance couplers, and their ability to withstand stresses during normal use. It is suitable for testing products with a rated current up to 16 A at room temperature, providing reliable data support for quality control, certification, and R&D in the electrical industry.

Technical Parameters

Parameter | Specification |

Model | ZLT-CS1, ZLT-CS2, ZLT-CS3 |

Rated Test Object | Plugs, socket-outlets, cable couplers, appliance couplers (≤16 A, ≤250 V) |

Test Stroke | 50 mm - 60 mm |

Test Speed | 30 strokes/min (≤16 A, ≤250 V); 15 strokes/min (other accessories) |

Test Cycles | 50 insertions/withdrawals (equivalent to 100 strokes) |

Power Supply | AC 220 V 50 Hz (customizable voltages/frequencies on request) |

Max Specimen Capacity | ZLT-CS1: 1 unit; ZLT-CS2: 2 units; ZLT-CS3: 3 units |

Test Plug Pins | Brass pins (with insulating sleeves if applicable), tolerance: 0-0.06 mm |

Pin Spacing Tolerance | +0.050 mm (nominal distance) |

Product Features

High-Precision Testing Mechanism

The machine is equipped with ball bearing guide slides (1-3 slides based on model) and spring-loaded supports for fastening specimens, ensuring stable and smooth movement during plug insertion/withdrawal. This structure minimizes mechanical errors, ensuring test results are consistent with international standard requirements.

Programmable Control System

Each slide is paired with a dedicated programmable control unit, featuring replaceable program modules that store "test rhythm" settings. Operators can easily adjust and monitor key parameters: number of strokes, stroke time, and current-on duration (time until the retracting stroke). Manual control buttons for cylinder pistons and cylinder actuation indicators further enhance operational flexibility.

Safety & Versatility

Safety sockets are integrated to connect specimens to external test voltages, preventing electrical hazards during testing. The machine supports multiple specimens simultaneously (up to 3 units for ZLT-CS3) and accepts custom power supplies, making it suitable for laboratories, manufacturing facilities, and certification bodies worldwide.

Application

This test machine is widely used in:

Quality inspection of household plugs and socket-outlets (rated current ≤16 A, rated voltage ≤250 V);

Durability testing of cable couplers and appliance couplers for home appliances (e.g., refrigerators, washing machines);

Compliance testing for electrical product certification (meeting IEC 60884-1 standards);

R&D and batch quality control in electrical equipment manufacturing plants.

FAQ

What standards does this machine comply with?

It fully complies with IEC 60884-1 figure 16 and clause 20, the international standard for testing the normal operation performance of household plug-and-socket accessories.

Why are there three models (ZLT-CS1/CS2/CS3)?

The models differ in max specimen capacity: ZLT-CS1 tests 1 specimen at a time, ZLT-CS2 tests 2, and ZLT-CS3 tests 3. This allows customers to choose based on testing efficiency needs (e.g., large manufacturers may prefer ZLT-CS3 for batch testing).

Can the test plug be customized for non-standard accessories?

Yes. The standard test plug uses brass pins with a tolerance of 0-0.06 mm, but we can provide customized plugs (e.g., different pin sizes, materials) for non-standard accessories upon request.