Product Overview

We specialize in manufacturing Cord Anchorage Testing Apparatus (Model: ZLT-DY2), a device designed to test the reliability of cable connections under intermittent tensile loads. Compliant with IEC 62196 figure 17 & clause 25.3 and IEC 60309 figure 6 & table 11, this apparatus focuses on EV (electric vehicle) plugs and vehicle connectors with flexible cables, evaluating whether their cord anchorage can withstand specified pulling forces without loosening or damage. It is a critical tool for ensuring safety in the new energy vehicle and electrical connector industries.

Technical Parameters

Parameter | Specification |

Model | ZLT-DY2 |

Brand | ZLTJC |

Compliant Standards | IEC 62196 (figure 17, clause 25.3); IEC 60309 (figure 6, table 11) |

Test Load Range | 160N - 600N (via weight set: 160N×1, 240N×2, 10N×1, 100N×2) |

Motor Configuration | AC geared motor + additional gear reduction; speed: ≈60 rpm |

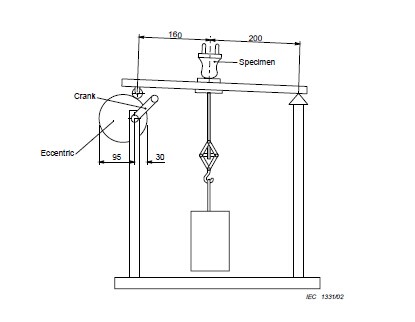

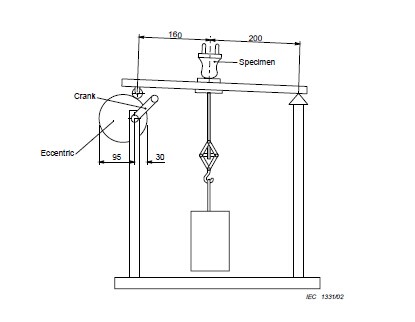

Eccentric Disc | Diameter: 125 mm; Eccentricity: 30 mm |

Counter Type | 4-digit resettable electronic counter (indicates number of strokes) |

Power Supply | AC 220 V 50 Hz (customizable voltages/frequencies on request) |

MOQ | 1 unit |

Lead Time | 10 days |

Shipping Port | Guangzhou, China |

Specimen Clamping | Multiple gripping dies (matches different cord sizes/shapes) |

Product Features

Adjustable & Precise Load Control

The apparatus includes a set of weights (160N×1, 240N×2, 10N×1, 100N×2) that can be combined to achieve 160N, 200N, 240N, 250N, 300N, 500N, or 600N test loads. This flexibility allows it to meet the tensile requirements of different EV plugs and vehicle connectors.

Stable Mechanical Transmission

A high-quality AC geared motor with additional gear reduction ensures a stable speed of ≈60 rpm, while the 125mm diameter eccentric disc (30mm eccentricity) generates smooth intermittent tensile forces. The lever with a track wheel further enhances force transmission stability, avoiding sudden load fluctuations that could affect test accuracy.

User-Friendly Design

The 4-digit resettable counter allows easy tracking of test strokes, and the clamping mechanism comes with multiple gripping dies to fit various cord sizes and shapes—no need for additional custom fixtures for most standard products. The basic frame with a protective housing also ensures operator safety during testing.

Application

This apparatus is widely used in:

EV plug manufacturers: Testing the cord anchorage of charging plugs (e.g., Type 2, CCS plugs) to ensure they withstand frequent plugging/unplugging and accidental pulling;

Vehicle connector producers: Evaluating the durability of flexible cable connections for on-board electrical systems;

New energy vehicle (NEV) manufacturers: Conducting incoming quality checks on EV charging accessories;

Certification labs: Verifying compliance with IEC 62196 and IEC 60309 standards for global market access (e.g., EU, Asia).

FAQ

What types of cables can this apparatus test?

It is designed for flexible cables used with EV plugs and vehicle connectors. The multiple gripping dies support cables of different sizes and cross-sections; custom dies can be provided for non-standard cable shapes.

How long does it take to deliver after ordering?

The standard lead time is 10 days from the date of order confirmation. For bulk orders or customized configurations (e.g., special power supplies), lead time may be extended slightly (we will confirm details before shipment).

Is the test load calibrated before delivery?

Yes. Every ZLT-DY2 apparatus undergoes factory calibration of test loads (160N-600N) using precision weighing equipment, and a calibration certificate is provided to ensure compliance with international standard requirements.