Product Overview

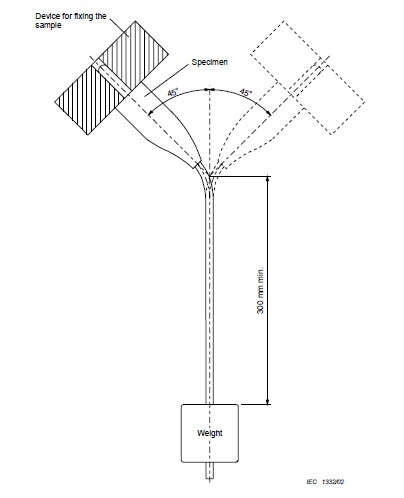

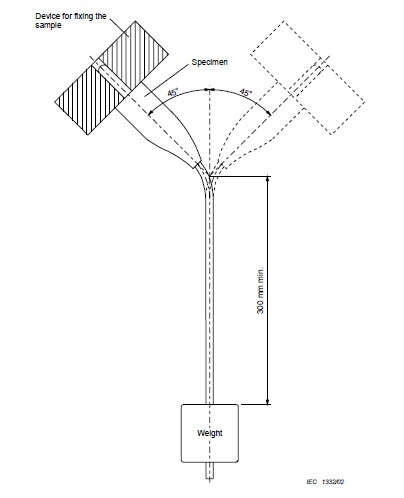

The Flexing Cycle Test Apparatus is a professional testing device engineered for continuous bending performance evaluations of cables through controlled swivelling movements. It is specifically designed to test up to 6 cables simultaneously—each fitted with plugs or cable entries from electric tools and hand lamps—ensuring alignment with real-world product configurations. This apparatus adheres to globally recognized standards including IEC60884-1 (Figure 21), VDE0620 (Figure 21), and UL 817 (Figure 11.3), making it a trusted tool for validating cable durability in compliance-driven industries. Equipped with a PLC (Programmable Logic Controller) for centralized control and operation, the device delivers automated testing, precise cycle counting, and reliable performance data, critical for quality assurance (QA) teams and manufacturers of electrical equipment.

Technical Parameters

Parameter Category | Specification Details |

Drive Mechanism | 1 electric drive motor integrated with reduction gear and swiveling gear |

Swiveling Angle | 45° or 90° (adjustable, measured on either side of the vertical axis) |

Weight Configuration | 6 sets of test weights (10N, 20N, 113g, 284g) to simulate real-world load conditions |

Swiveling Frequency | Adjustable range: 10~60 rpm (rotations per minute) |

Counter System | - 1 x 6-digit predetermining counter (automatically shuts down drive at target cycles)- 6 x 5-digit individual counters (records swivels at sample open-circuit events) |

Sample Fixing | Dedicated device for secure, stable positioning of test samples |

Power Supply | Standard: A.C. 220V 50Hz; Custom voltages/frequencies available upon request |

Product Features

High Throughput Testing

By supporting simultaneous testing of 6 cables, the apparatus cuts down test lead times significantly compared to single-sample testers. This efficiency is ideal for high-volume production lines where rapid QA validation is essential to meet delivery schedules.

PLC-Powered Precision

The integrated PLC control system eliminates manual operation errors, ensuring consistent swiveling angles, frequencies, and weight applications across all test samples. This precision guarantees reproducible results, a key requirement for compliance testing.

Flexible Operational Tuning

Users can adjust the swiveling frequency (10~60 rpm) to mimic varying usage intensities (e.g., frequent bending for portable tools vs. occasional movement for stationary lamps). The diverse weight set (10N, 20N, 113g, 284g) also allows testing of cables with different load-bearing requirements.

Comprehensive Event Tracking

The dual-counter setup provides full visibility into test progress: the 6-digit predetermining counter prevents over-testing by stopping the drive at the target cycle count, while the 5-digit individual counters immediately log open-circuit events—enabling quick identification of underperforming cables.

Global Standard Alignment

Compliance with IEC60884-1, VDE0620, and UL 817 ensures test results are accepted in major markets (Europe, North America, Asia), reducing barriers for manufacturers exporting electrical tools, hand lamps, and cable-equipped appliances.

Application

The Flexing Cycle Test Apparatus is widely used in industries and scenarios focused on cable durability validation:

Electric tool manufacturing: Testing cables for drills, grinders, and sanders—devices where cables endure frequent, repetitive bending during operation.

Hand lamp production: Evaluating cables for portable work lights, emergency lamps, and camping lanterns to ensure resistance to bending fatigue.

Small appliance QA: Validating cables for portable fans, heaters, and blenders, ensuring long-term reliability under household use.

Compliance laboratories: Conducting third-party certification tests for electrical products to meet international safety and performance standards.

Component suppliers: Verifying cable assemblies before supplying to original equipment manufacturers (OEMs) in the electrical sector.

FAQ

Which standards does this Flexing Cycle Test Apparatus comply with?

The apparatus fully meets the requirements of IEC60884-1 (Figure 21), VDE0620 (Figure 21), and UL 817 (Figure 11.3)—three of the most authoritative standards for cable bending tests in the global electrical industry.

How many cables can be tested at once?

It can test up to 6 cables simultaneously, each fitted with plugs or cable entries from electric tools or hand lamps, maximizing testing efficiency.

Is the swiveling frequency adjustable?

Yes, the swiveling frequency can be tuned between 10~60 rpm to simulate different real-world usage patterns for the tested cables.

How does the apparatus track open-circuit issues?

It is equipped with 6 sets of 5-digit counters (one per test cable) that automatically record the number of swivels when a sample experiences an open circuit, allowing precise performance tracking for each cable.

Can the power supply be customized for regional needs?

A5: Absolutely. The standard power supply is A.C. 220V 50Hz, but custom voltages (e.g., 110V) and frequencies (e.g., 60Hz) are available upon request to match regional electrical specifications.